+86-574-86597612

+86-574-86597612

| Menovitý priemer otvoru | Odchýlka | Variácia | Variácia | Odchýlka šírky prsteňa | Radiálne hádzanie | Odchýlka šírky prsteňa | |||

| <= | <= | △dmp | Vdp | Vdmp | △Bs | Kia | △Ts | △T1s | △T2s |

| 10 18 | 0-12 | 12 | 9 | 0 - 120 | 15 | 2000 | 1000 | 1000 | |

| 18 30 | 0-12 | 12 | 9 | 0 - 120 | 18 | 2000 | 1000 | 1000 | |

| 30 50 | 0-12 | 12 | 9 | 0 - 120 | 20 | 2000 | 1000 | 1000 | |

| 50 80 | 0-15 | 15 | 11 | 0 - 150 | 25 | 2000 | 1000 | 1000 | |

| 80 120 | 0-20 | 20 | 15 | 0 - 200 | 30 | 200 -200 | 100 -100 | 100 -100 | |

| 120 180 | 0-25 | 25 | 19 | 0 - 250 | 35 | 350 -250 | 150-150 | 200 -100 | |

| 180 250 | 0-30 | 30 | 23 | 0 - 300 | 50 | 350 -250 | 150 -150 | 200 -100 | |

| 250 315 | 0-35 | 35 | 26 | 0 - 350 | 60 | 350 -250 | 150 -150 | 200 -100 | |

| 315 400 | 0-40 | 40 | 30 | 0 - 400 | 70 | 400 -400 | 200 - 200 | 200 - 200 | |

| 400 500 | 0 -45 | 45 | 34 | 0 -450 | 85 | 400 -400 | |||

| 500 630 | 0 -50 | 50 | 38 | 0 -500 | 100 | 500 – 500 | |||

| 630 800 | 0 -75 | 75 | 56 | 0 -750 | 120 | 600 -600 | |||

| 800 1000 | 0 -100 | 100 | 75 | 0 -1 000 | 120 | 750 -750 | |||

| 1000 1250 | 0 - 1250 | 0 - 1250 | 120 | 1000 -1000 | |||||

| 1250 1600 | 0 - 160 | 0 - 1600 | 120 | 1500 -1500 | |||||

| 1600 2000 | 0 - 200 | 0-2000 | 120 | 1500 -1500 | |||||

| Nominálny vonkajší priemer | Odchýlka | Variácia | Variácia | Radiálne hádzanie | |

| <= | <= | △Dmp | VDp | VDmp | Kia |

| 18 30 | 0 -12 | 12 | 9 | 18 | |

| 30 50 | 0 -14 | 14 | 11 | 20 | |

| 50 80 | 0 -16 | 16 | 12 | 25 | |

| 80 120 | 0 -18 | 18 | 14 | 35 | |

| 120 150 | 0 -20 | 20 | 15 | 40 | |

| 150 180 | 0 -25 | 25 | 19 | 45 | |

| 180 250 | 0 -30 | 30 | 23 | 50 | |

| 250 315 | 0 -35 | 35 | 26 | 60 | |

| 315 400 | 0 -40 | 40 | 30 | 70 | |

| 400 500 | 0 -45 | 45 | 34 | 80 | |

| 500 630 | 0 -50 | 50 | 38 | 100 | |

| 630 800 | 0 -70 | 70 | 55 | 120 | |

| 800 1 000 | 0 -100 | 100 | 75 | 120 | |

| 1000 1250 | 0 -125 | 125 | 94 | 120 | |

| 1250 1600 | 0 -160 | 160 | 120 | 120 | |

| 1600 2000 | 0 - 200 | 120 | |||

| 2000 2500 | 0 - 250 | | |||

| Menovitý priemer otvoru | Odchýlka | Variácia | Variácia | Odchýlka šírky prsteňa | Radiálne hádzanie | Odchýlka šírky prsteňa | |||

| <= | <= | △dmp | Vdp | Vdmp | △Bs | Kia | △Ts | △T1s | △T2s |

| 10 18 | 0-12 | 12 | 9 | 0-50 | 15 | 100 0 | 50-0 | 50-0 | |

| 18 30 | 0-12 | 12 | 9 | 0-50 | 18 | 100 0 | 50-0 | 50-0 | |

| 30 50 | 0-12 | 12 | 9 | 0-50 | 20 | 100 0 | 50-0 | 50-0 | |

| 50 80 | 0 -15 | 15 | 11 | 0-50 | 25 | 100 0 | 50-0 | 50-0 | |

| 80 120 | 0-20 | 20 | 15 | 0-50 | 30 | 100 0 | 50-0 | 50-0 | |

| 120 180 | 0-25 | 25 | 19 | 0-50 | 35 | 150 0 | 50-0 | 100~0 | |

| 180 250 | 0-30 | 30 | 23 | 0-50 | 50 | 150 0 | 50-0 | 100~0 | |

| 250 315 | 0-35 | 35 | 26 | 0-50 | 60 | 200 0 | 100~0 | 100~0 | |

| 315 400 | 0-40 | 40 | 30 | 0-50 | 70 | 200 0 | 100~0 | 100~0 | |

| 400 500 | |||||||||

| 500 630 | |||||||||

| 630 800 | |||||||||

| 800 1000 | |||||||||

Vonkajší prstenec

Trieda tolerancie P6X

| Nominálny vonkajší priemer | Odchýlka | Variácia | Variácia | Odchýlka šírky prsteňa | Radiálne hádzanie | |

| <= | <= | △Dmp | VDp | VDmp | △Cs | Kea |

| 18 30 | 0 -12 | 12 | 9 | 0 -100 | 18 | |

| 30 50 | 0 -14 | 14 | 11 | 0 -100 | 20 | |

| 50 80 | 0 -16 | 16 | 12 | 0 -100 | 25 | |

| 80 120 | 0 -18 | 18 | 14 | 0 -100 | 35 | |

| 120 150 | 0 -20 | 20 | 15 | 0 -100 | 40 | |

| 150 180 | 0 -25 | 25 | 19 | 0 -100 | 45 | |

| 180 250 | 0 -30 | 30 | 23 | 0 -100 | 50 | |

| 250 315 | 0 -35 | 35 | 26 | 0 -100 | 60 | |

| 315 400 | 0 -40 | 40 | 30 | 0 -100 | 70 | |

| 400 500 | 0 -45 | 45 | 34 | 0 -100 | 80 | |

| 500 630 | 0 -50 | 50 | 38 | 0 -100 | 100 | |

| 630 800 | ||||||

| 800 1 000 | ||||||

Tolerancia šírky △Cs je totožná s △Bs vnútorného krúžku toho istého ložiska

Tolerancie pre metrické kuželíkové ložiská DHK (okrem kuželíkových ložísk)

Všetky rozmery sú uvedené v (mm):

Tolerancie v (um):

Vnútorný krúžok

Trieda tolerancie P5

| Menovitý priemer otvoru | Odchýlka | Variácia | Variácia | Odchýlka šírky prsteňa | Radiálne hádzanie | Výbeh na bočnej strane | ||

| <= | <= | △dmp | Vdp | Vdmp | △Bs | Kia | d | △Ts |

| 10 18 | 0 -7 | 5 | 5 | 0 -200 | 5 | 7 | 200 - 200 | |

| 18 30 | 0 -8 | 6 | 5 | 0 -200 | 5 | 8 | 200 - 200 | |

| 30 50 | 0 -10 | 8 | 5 | 0 -240 | 6 | 8 | 200 - 200 | |

| 50 80 | 0 -12 | 9 | 6 | 0 -300 | 7 | 8 | 200 - 200 | |

| 80 120 | 0 -15 | 11 | 8 | 0 -400 | 8 | 9 | 200 - 200 | |

| 120 180 | 0 -18 | 14 | 9 | 0 – 500 | 11 | 10 | 350 -250 | |

| 180 250 | 0 -22 | 17 | 11 | 0 -600 | 13 | 11 | 350 -250 | |

| 250 315 | 0 -25 | 19 | 13 | 0 -700 | 16 | 13 | 350 -250 | |

| 315 400 | 0 -30 | 23 | 15 | 0 -800 | 19 | 15 | 400 - 400 | |

| 400 500 | 0 -35 | 26 | 18 | 0 -900 | 22 | 17 | 400 - 400 | |

| 500 630 | 0 -40 | 30 | 20 | 0 – 1000 | 26 | 20 | 500 - 500 | |

| 630 800 | 0 -50 | 50 | 25 | 0 -1500 | 30 | 26 | 600 - 600 | |

| 800 1000 | 0 -65 | 60 | 30 | 0 -2000 | 35 | 32 | 750 - 750 | |

Vonkajší prstenec

Trieda tolerancie P5

| Nominálny vonkajší priemer | Odchýlka | Variácia | Variácia | Radiálne hádzanie | Variácia vonkajšieho sklonu | |

| <= | <= | △Dmp | VDp | VDmp | Kea | |

| 18 30 | 0 -8 | 6 | 5 | 6 | 8 | |

| 30 50 | 0 -9 | 7 | 5 | 7 | 8 | |

| 50 80 | 0 -11 | 8 | 6 | 8 | 8 | |

| 80 120 | 0 -13 | 10 | 7 | 10 | 9 | |

| 120 150 | 0 -15 | 11 | 8 | 11 | 10 | |

| 150 180 | 0 -18 | 14 | 9 | 13 | 10 | |

| 180 250 | 0 -20 | 15 | 10 | 15 | 11 | |

| 250 315 | 0 -25 | 19 | 13 | 18 | 13 | |

| 315 400 | 0 -28 | 22 | 14 | 20 | 13 | |

| 400 500 | 0 -33 | 25 | 17 | 23 | 15 | |

| 500 630 | 0 -38 | 29 | 19 | 25 | 18 | |

| 630 800 | 0 -45 | 34 | 23 | 30 | 20 | |

| 800 1 000 | 0 -60 | 45 | 30 | 35 | 25 | |

| 1000 1250 | 0 -80 | 75 | 38 | 40 | 30 | |

| 1250 1600 | 0 -100 | 90 | 45 | 45 | 35 | |

Tolerancia šírky △Cs je totožná s △Bs vnútorného krúžku toho istého ložiska

Tolerancie pre metrické kuželíkové ložiská DHK (okrem kuželíkových ložísk)

Všetky rozmery sú uvedené v (mm):

Tolerancie v (um):

Vnútorný krúžok

Trieda tolerancie P4

| Menovitý priemer otvoru | Odchýlka | Variácia | Variácia | Odchýlka šírky prsteňa | Radiálne hádzanie | Výbeh na bočnej strane | Výbeh na bočnej strane | Odchýlka šírky prsteňa | |

| <= | <= | △dmp △ds | Vdp | Vdmp | △Bs | kia | SD | Sia | △Ts |

| 10 18 | 0 -5 | 4 | 4 | 0 -200 | 3 | 3 | 3 | 200 -200 | |

| 18 30 | 0 -6 | 5 | 4 | 0 -200 | 3 | 4 | 4 | 200 -200 | |

| 30 50 | 0 -7 | 6 | 5 | 0 -240 | 4 | 4 | 4 | 200 -200 | |

| 50 80 | 0 -8 | 7 | 5 | 0 -300 | 4 | 5 | 4 | 200 -200 | |

| 80 120 | 0 -10 | 8 | 5 | 0 -400 | 5 | 5 | 5 | 200 -200 | |

| 120 180 | 0 -13 | 10 | 7 | 0 – 500 | 6 | 6 | 7 | 350 -250 | |

| 180 250 | 0 -15 | 11 | 8 | 0 -600 | 8 | 7 | 8 | 350 -250 | |

Vonkajší prstenec

Trieda tolerancie P4

| Nominálny vonkajší priemer | Odchýlka | Variácia | Variácia | Radiálne hádzanie | Variácia vonkajšieho sklonu | Výbeh na bočnej strane | |

| <= | <= | △Dmp △Ds | VDp | VDmp | Kea | SD | More |

| 18 30 | 0 -6 | 5 | 4 | 4 | 4 | 5 | |

| 30 50 | 0 -7 | 5 | 5 | 5 | 4 | 5 | |

| 50 80 | 0 -9 | 7 | 5 | 5 | 4 | 5 | |

| 80 130 | 0 -10 | 8 | 5 | 6 | 5 | 6 | |

| 130 150 | 0 -11 | 8 | 6 | 7 | 5 | 7 | |

| 150 180 | 0 -13 | 10 | 7 | 8 | 5 | 8 | |

| 180 250 | 0 -15 | 11 | 8 | 10 | 7 | 10 | |

| 250 315 | 0 -18 | 14 | 9 | 11 | 8 | 10 | |

| 315 400 | 0 -20 | 15 | 10 | 13 | 10 | 13 | |

Tolerancia šírky △Cs a VCs sú identické s△Bs a VBs vnútorného krúžku toho istého ložiska

| Priemer priemeru. (mm) | Axiálna vnútorná vôľa Séria (μm) | ||||||

| > | <= | 329 Min max | 320 Min max X | 330 Min max | 331, 3, 2, 332, 332 Min max | 303, 323 Min max | 313 Min max |

| -- 30 | -- -- | 80 120 | -- -- | 100 140 | 130 170 | 60 100 | |

| 30 40 | -- -- | 100 140 | -- -- | 120 160 | 140 180 | 70 110 | |

| 40 50 | -- -- | 120 160 | 180 220 | 140 180 | 160 200 | 80 120 | |

| 50 65 | -- -- | 140 180 | 200 240 | 160 200 | 180 220 | 100 140 | |

| 65 80 | -- -- | 160 200 | 250 290 | 180 220 | 200 260 | 110 170 | |

| 80 100 | 270 310 | 190 230 | 350 390 | 210 270 | 240 300 | 110 170 | |

| 100 120 | 270 330 | 220 280 | 340 400 | 220 280 | 280 340 | 130 190 | |

| 120 140 | 310 370 | 240 300 | 340 400 | 240 300 | 330 390 | 160 220 | |

| 140 160 | 370 430 | 270 330 | 340 400 | 270 330 | 370 430 | 180 240 | |

| 160 180 | 370 430 | 310 370 | -- -- | 310 370 | 390 450 | -- -- | |

| 180 190 | 370 430 | 340 400 | -- -- | 340 400 | 440 500 | -- -- | |

| 190 200 | 390 450 | 340 400 | -- -- | 340 400 | 440 500 | -- -- | |

| 200 225 | 440 500 | 390 450 | -- -- | 390 450 | 490 550 | -- -- | |

| 225 250 | 440 500 | 440 500 | -- -- | 440 500 | 540 600 | -- -- | |

| 250 280 | 540 500 | 490 55 | -- -- | 490 550 | -- -- | -- -- | |

| 280 300 | 640 700 | 540 600 | -- -- | 540 600 | -- -- | -- -- | |

| 300 340 | 640 700 | 590 650 | -- -- | 590 650 | -- -- | -- -- | |

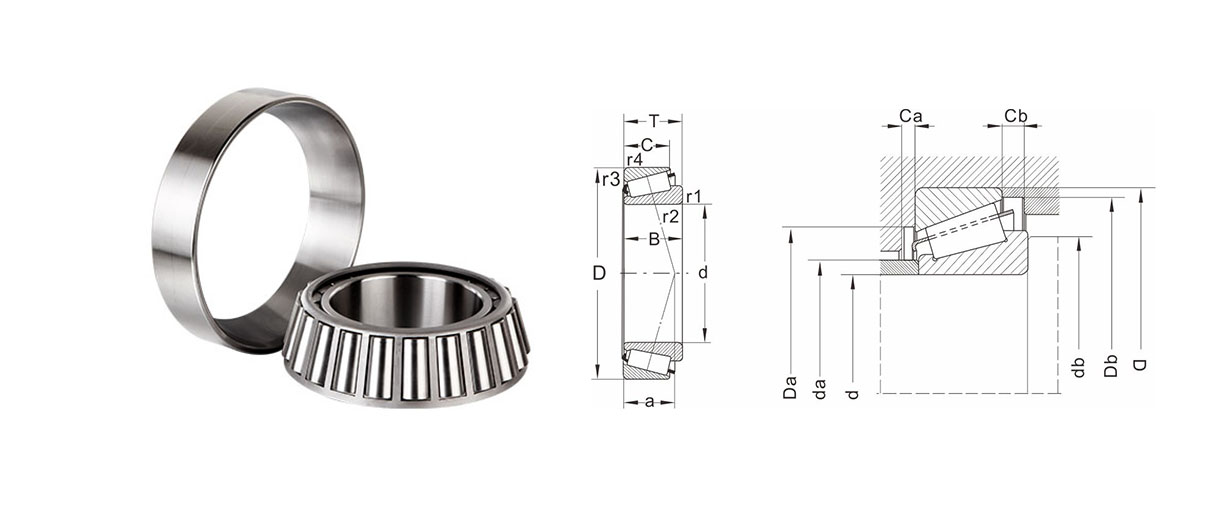

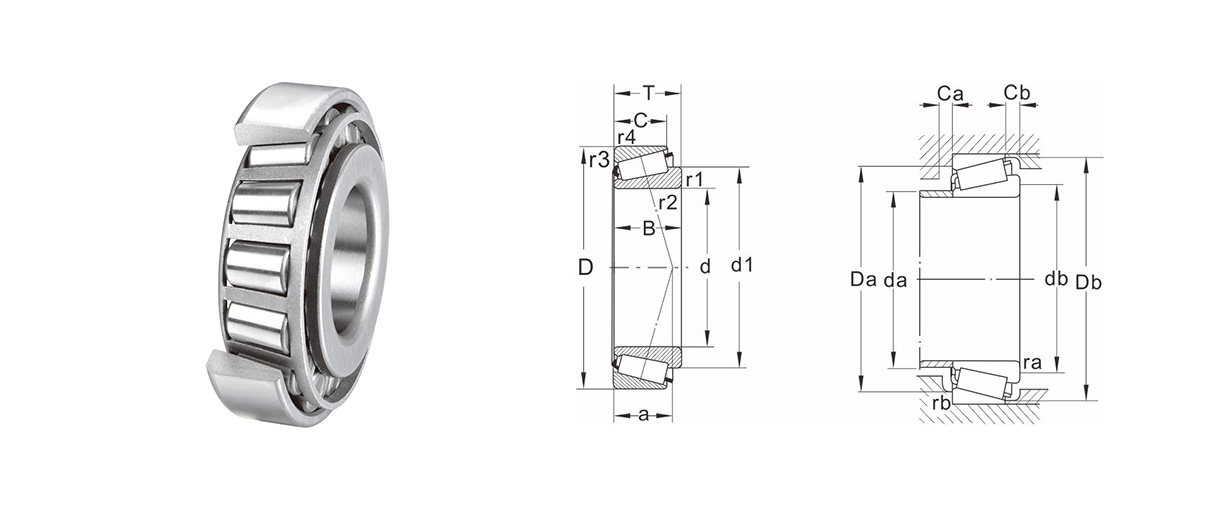

| Model | Rozmery | Extrémna rýchlosť | Menovité zaťaženie | Faktor výpočtu | Rozmery podpery a zaoblenia (mm) | Hmotnosť [kg] | |||||||||||||||||

DIN720 | ISO355 | d | D | B | C | T | r1,r2 min | r3,r4 min | a | Mazanie tukom | Olejové mazanie | Dynamické zaťaženie | Statické zaťaženie | e | Y | Áno | Da max | db min | min | Db min | Cca min | Cb min | |

33009 | T2CE045 | 45 | 75 | 24 | 19 | 24 | 1 | 1 | 16 | 4000 | 5000 | 72 | 104 | 0.29 | 2.04 | 1.2 | 51 | 51 | 67 | 71 | 4 | 5 | 0.43 |

33010 | T2CE050 | 50 | 80 | 24 | 19 | 24 | 1 | 1 | 17 | 4500 | 6000 | 75 | 114 | 0.32 | 1.9 | 1.04 | 56 | 56 | 72 | 76 | 4 | 5 | 0.42 |

33011 | T2CE055 | 55 | 90 | 27 | 21 | 27 | 1.5 | 1.5 | 19 | 4000 | 5300 | 93 | 143 | 0.31 | 1.92 | 1.06 | 63 | 62 | 81 | 86 | 5 | 6 | 0.67 |

33012 | T2CE060 | 60 | 95 | 27 | 21 | 27 | 1.5 | 1.5 | 20 | 3800 | 5000 | 96.5 | 150 | 0.33 | 0.83 | 1.01 | 67 | 67 | 85 | 90 | 5 | 6 | 0.73 |

33013 | T2CE065 | 65 | 100 | 27 | 21 | 27 | 1.5 | 1.5 | 21 | 3400 | 4500 | 100 | 163 | 0.35 | 1.72 | 0.95 | 72 | 72 | 89 | 96 | 5 | 6 | 0.78 |

33013 | T2CE080 | 80 | 125 | 36 | 29.5 | 36 | 1.5 | 1.5 | 26 | 2600 | 3600 | 176 | 290 | 0.28 | 2.16 | 1.19 | 90 | 87 | 112 | 119 | 6 | 6.5 | 1.67 |

33014 | T2CE070 | 70 | 110 | 31 | 25.5 | 31 | 1.5 | 1.5 | 22 | 3200 | 4300 | 137 | 224 | 0.28 | 2.11 | 1.16 | 78 | 77 | 99 | 105 | 5 | 5.5 | 1.14 |

33015 | T2CE075 | 75 | 115 | 31 | 25.5 | 31 | 1.5 | 1.5 | 23 | 3000 | 4000 | 140 | 232 | 0.3 | 2.01 | 1.11 | 83 | 82 | 104 | 110 | 6 | 5.5 | 1.12 |

33017 | T2CE085 | 85 | 130 | 36 | 29.5 | 36 | 1.5 | 1.5 | 26 | 2600 | 3600 | 183 | 315 | 0.29 | 2.06 | 1.13 | 94 | 92 | 118 | 125 | 6 | 6.5 | 1.76 |

33018 | T2CE090 | 90 | 140 | 39 | 32.5 | 39 | 2 | 1.5 | 28 | 2200 | 3200 | 216 | 365 | 0.27 | 2.23 | 1.23 | 100 | 99 | 127 | 135 | 7 | 6.5 | 2.3 |

33019 | T2CE095 | 95 | 145 | 39 | 32.5 | 39 | 2 | 1.5 | 29 | 2200 | 3200 | 220 | 380 | 0.28 | 2.16 | 1.19 | 104 | 104 | 131 | 139 | 1 | 6.5 | 2.24 |

33020 | T2CE100 | 100 | 150 | 39 | 32.5 | 39 | 2 | 1.5 | 29 | 2000 | 3000 | 224 | 400 | 0.29 | 2.09 | 1.15 | 108 | 109 | 135 | 143 | 7 | 6.5 | 2.33 |

33021 | T2DE105 | 105 | 160 | 43 | 34 | 43 | 2.5 | 2 | 31 | 1900 | 2800 | 265 | 450 | 0.28 | 2.12 | 1.17 | 116 | 115 | 145 | 153 | 7 | 9 | 3.09 |

33022 | T2DE110 | 110 | 170 | 47 | 37 | 47 | 2.5 | 2 | 33 | 1800 | 2600 | 300 | 520 | 0.29 | 20.9 | 1.15 | 123 | 120 | 152 | 161 | 7 | 10 | 3.71 |

33024 | T2DE120 | 120 | 180 | 48 | 38 | 48 | 2.5 | 2 | 36 | 1800 | 2600 | 310 | 560 | 0.31 | 1.97 | 1.08 | 132 | 130 | 160 | 171 | 6 | 10 | 4.06 |

33026 | -- | 130 | 200 | 55 | 43 | 55 | 2.5 | 2 | -- | 1500 | 2000 | 390 | 705 | 0.34 | 1.76 | 0.97 | 142 | 143 | 178 | 192 | -- | -- | 6.19 |

33028 | -- | 140 | 210 | 56 | 44 | 86 | 2.5 | 2 | -- | 1500 | 2000 | 406 | 758 | 0.36 | 1.37 | 0.92 | 152 | 152 | 186 | 202 | -- | -- | 6.61 |

33030 | -- | 150 | 225 | 59 | 46 | 59 | 3 | 2.5 | -- | 1500 | 2000 | 457 | 865 | 0.37 | 1.6 | 0.9 | 162 | 164 | 213 | 217 | -- | -- | 8.15 |

33108 | T2CE040 | 40 | 75 | 26 | 20.5 | 26 | 1.5 | 1.5 | 18 | 5000 | 6700 | 80 | 104 | 0.36 | 1.69 | 0.93 | 47 | 47 | 65 | 71 | 4 | 5.5 | 0.52 |

33109 | T3CE045 | 45 | 80 | 26 | 20.5 | 26 | 1.5 | 1.5 | 19 | 4500 | 6000 | 85 | 116 | 0.38 | 1.57 | 0.86 | 52 | 52 | 69 | 77 | 4 | 5.5 | 0.53 |

33110 | T3CE050 | 50 | 85 | 26 | 20 | 26 | 1.5 | 1.5 | 20 | 4300 | 5600 | 86.5 | 122 | 0.41 | 1.46 | 0.8 | 56 | 57 | 74 | 82 | 4 | 6 | 0.6 |

33111 | T3CE055 | 55 | 95 | 30 | 23 | 30 | 1.5 | 1.5 | 22 | 3800 | 5000 | 114 | 163 | 0.37 | 1.6 | 0.88 | 62 | 62 | 83 | 91 | 5 | 7 | 0.89 |

33112 | T3CE060 | 60 | 100 | 30 | 23 | 30 | 1.5 | 1.5 | 23 | 3600 | 4800 | 116 | 173 | 0.4 | 1.51 | 0.83 | 67 | 67 | 88 | 96 | 5 | 7 | 0.89 |

33113 | T3CE065 | 65 | 110 | 34 | 26.5 | 34 | 1.5 | 1.5 | 26 | 3200 | 4300 | 150 | 228 | 0.39 | 1.55 | 0.85 | 73 | 72 | 96 | 106 | 6 | 7.5 | 1.34 |

33113 | T3DE080 | 80 | 130 | 37 | 29 | 37 | 2 | 1.5 | 31 | 2600 | 3600 | 190 | 300 | 0.42 | 1.44 | 0.79 | 89 | 89 | 114 | 126 | 6 | 8 | 1.93 |

33114 | T3DE070 | 70 | 120 | 37 | 29 | 37 | 2 | 1.5 | 28 | 3000 | 4000 | 176 | 260 | 0.38 | 1.58 | 0.87 | 79 | 79 | 104 | 115 | 6 | 8 | 1.75 |

33115 | T3DE075 | 75 | 125 | 37 | 29 | 37 | 2 | 1.5 | 30 | 2800 | 3800 | 180 | 275 | 0.4 | 1.51 | 0.83 | 84 | 84 | 109 | 120 | 6 | 8 | 1.74 |

33117 | T3DE085 | 85 | 140 | 41 | 32 | 41 | 2.5 | 1.5 | 33 | 2400 | 3400 | 220 | 355 | 0.41 | 1.48 | 0.81 | 95 | 95 | 122 | 135 | 7 | 9 | 2.38 |

33118 | T3DE090 | 90 | 150 | 45 | 35 | 45 | 2.5 | 2 | 36 | 2000 | 3000 | 265 | 425 | 0.4 | 1.51 | 0.83 | 100 | 100 | 130 | 144 | 7 | 10 | 3.07 |

33120 | -- | 100 | 165 | 52 | 40 | 52 | 2.5 | 2 | -- | 2000 | 3000 | 325 | 523 | 0.41 | 1.48 | 0.81 | 112 | 12 | 142 | 142 | -- | -- | 4.29 |

33121 | -- | 105 | 175 | 56 | 44 | 56 | 2.5 | 2 | -- | 1700 | 2400 | 360 | 307 | 0.4 | 1.48 | 0.82 | 117 | 116 | 150 | 150 | -- | -- | 5.33 |

33122 | -- | 110 | 180 | 56 | 43 | 56 | 2.5 | 2 | -- | 1800 | 2600 | 369 | 630 | 0.43 | 1.4 | 0.8 | 120 | 121 | 170 | 174 | -- | -- | 5.55 |

33124 | -- | 120 | 200 | 62 | 48 | 62 | 2.5 | 2 | -- | 1700 | 2400 | 462 | 785 | 0.35 | 1.7 | 0.95 | 132 | 133 | 172 | 192 | -- | -- | 7.73 |

33205 | T2DE025 | 25 | 52 | 22 | 18 | 22 | 1 | 1 | 14 | 4200 | 10000 | 49 | 58.5 | 0.35 | 1.71 | 0.94 | 30 | 31 | 43 | 49 | 4 | 4 | 0.22 |

33206 | T2DE030 | 30 | 62 | 25 | 19.5 | 25 | 1 | 1 | 16 | 6000 | 8000 | 65.5 | 78 | 0.34 | 1.76 | 0.97 | 36 | 36 | 53 | 59 | 5 | 5.5 | 0.35 |

33207 | T2DE035 | 35 | 72 | 28 | 22 | 28 | 1.5 | 1.5 | 18 | 5300 | 7000 | 86.5 | 106 | 0.35 | 1.7 | 0.93 | 42 | 42 | 61 | 68 | 5 | 6 | 0.59 |

33208 | T2DE040 | 40 | 80 | 32 | 25 | 32 | 1.5 | 1.5 | 21 | 4500 | 6000 | 106 | 134 | 0.36 | 1.68 | 0.92 | 47 | 47 | 67 | 76 | 5 | 7 | 0.74 |

33209 | T3DE045 | 45 | 85 | 32 | 25 | 32 | 1.5 | 1.5 | 22 | 4300 | 5600 | 108 | 146 | 0.39 | 1.56 | 0.86 | 52 | 52 | 72 | 81 | 5 | 7 | 0.79 |

33210 | T3DE050 | 50 | 90 | 32 | 24.5 | 32 | 1.5 | 1.5 | 23 | 3800 | 5000 | 114 | 163 | 0.41 | 1.45 | 0.8 | 57 | 57 | 77 | 87 | 5 | 7.5 | 0.85 |

33211 | T3DE055 | 55 | 100 | 35 | 27 | 35 | 2 | 1.5 | 26 | 3400 | 4500 | 137 | 196 | 0.4 | 1.5 | 0.83 | 62 | 64 | 85 | 96 | 6 | 8 | 1.21 |

33212 | T3EE060 | 60 | 110 | 38 | 29 | 38 | 2 | 1.5 | 28 | 3000 | 4000 | 170 | 240 | 0.4 | 1.48 | 0.82 | 69 | 69 | 93 | 105 | 6 | 9 | 1.5 |

33213 | T3EE065 | 65 | 120 | 42 | 32 | 41 | 2 | 1.5 | 30 | 2800 | 3800 | 204 | 285 | 0.39 | 1.54 | 0.85 | 74 | 74 | 102 | 115 | 6 | 9 | 2.04 |

33214 | T3EE070 | 70 | 125 | 41 | 32 | 41 | 2 | 1.5 | 31 | 2600 | 3600 | 212 | 300 | 0.41 | 1.47 | 0.81 | 79 | 79 | 107 | 120 | 7 | 9 | 2.06 |

33215 | T3EE075 | 75 | 130 | 41 | 31 | 41 | 2 | 1.5 | 32 | 2400 | 3400 | 208 | 310 | 0.43 | 1.4 | 0.77 | 83 | 84 | 111 | 125 | 7 | 10 | 2.24 |

33216 | T3EE080 | 80 | 140 | 46 | 35 | 46 | 2.5 | 2 | 35 | 2200 | 3200 | 250 | 390 | 0.43 | 1.41 | 0.78 | 89 | 90 | 119 | 135 | 7 | 11 | 3.01 |

33217 | T3EE085 | 85 | 150 | 49 | 37 | 49 | 2.5 | 2 | 37 | 2000 | 3000 | 290 | 440 | 0.42 | 1.43 | 0.79 | 95 | 95 | 128 | 144 | 7 | 12 | 3.5 |

33220 | -- | 100 | 180 | 63 | 48 | 63 | 3 | 2.5 | -- | 1700 | 2400 | 429 | 655 | 0.4 | 1.5 | 0.8 | 112 | 112 | 151 | 151 | -- | -- | 6.95 |

33221 | -- | 105 | 190 | 68 | 52 | 68 | 3 | 2.5 | -- | 1800 | 2600 | 497 | 790 | 0.4 | 1.49 | 0.82 | 119 | 117 | 159 | 159 | -- | -- | 8.43 |

Dlhoročné pracovné skúsenosti

Zákaznícky servis

Patentovaná technológia

Ningbo DHK Precision Bearing Co, Ltd (skrátene „DHK“) je špecializovaný podnik zaoberajúci sa výskumom a vývojom, výrobou a predajom ložísk, ktorý sa nachádza v zóne hospodárskeho rozvoja Ningbo Zhenhai s pohodlnou dopravou. Od založenia už viac ako desať rokov boli „technológia“, „kvalita“ a „služby“ vždy prvotnými problémami v našej mysli v záujme rozvoja. Poskytujeme spoľahlivé produkty a špeciálne prispôsobené služby pre globálne podniky v ťažkom priemysle a získali sme spokojnosť a získali dobrú povesť mnohých podnikov doma iv zahraničí.

DHK vyrába predovšetkým valčekové ložiská, kužeľové ložiská, naklápacie valivé ložiská, guľkové ložiská, ako aj rôzne druhy neštandardných ložísk a ložísk so špeciálne upraveným povrchom. Ložiská DHK boli doteraz široko používané v takých oblastiach, ako sú strojárske stroje, priemyselné čerpadlá, obrábacie stroje, kompresné motory, prevodovky, veterná energia a metalurgia vo vyspelých európskych a amerických krajinách.

DHK má meraciu miestnosť a inšpekčnú miestnosť ložísk v tomto odvetví a celosvetovo zaviedla špičkové inšpekčné zariadenia a zaviedla systém kontroly kvality v Číne, čím zaručuje kvalitu výrobkov všestranným spôsobom.

2024-12-02 Správy z priemyslu

2024-11-25 Správy z priemyslu

2024-11-18 Správy z priemyslu

2024-11-11 Správy z priemyslu

2024-11-04 Správy z priemyslu

2024-10-28 Správy z priemyslu

Kontaktujte nás a získajte prioritu cenovej ponuky, aby ste sa dozvedeli o našom novom produkte!